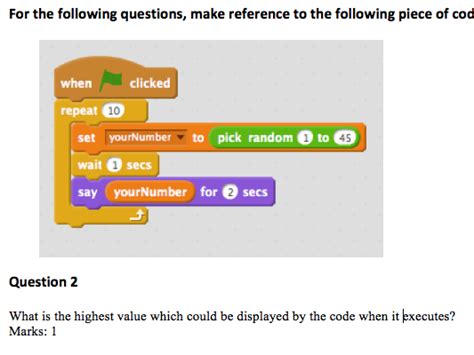

scratch test research|scratch test for coating : factory Scratch testing is a simple and rapid method of characterizing coatings, but results obtained are influenced by various factors such as coating thickness, substrate mechanical properties, . 3 dias atrás · Welcome to the Something Unlimited Wiki! A wiki centered around Gunsmoke Games' Something Unlimited, an adult parody game primarily based on the DCAU. Categories. Community content is available under CC-BY-SA unless otherwise noted.

{plog:ftitle_list}

web16 de jun. de 2023 · Deadloch Season 1 Episode 5 Recap. While Cath drives, Dulcie, Abby, and Eddie discuss the case under a blanket in the back of a truck. The goal of them being in the truckbed is to avoid the press as they head into the office. However, the back door is closed, and the press spots them, and Ray calls them to let them know another body has .

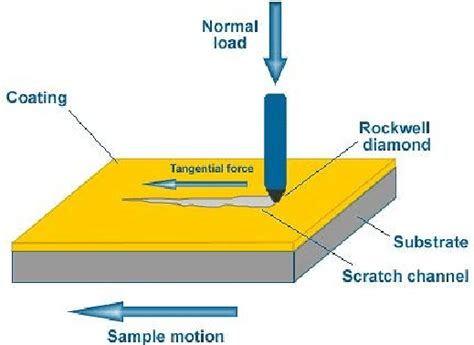

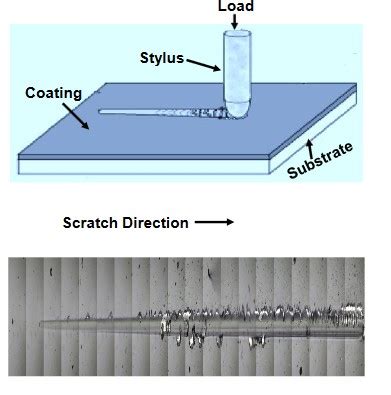

The scratch test is a quasi-non-destructive method made up of pushing a tool across the surface of a weaker rock at a given penetration depth. The unconfined compressive .We would like to show you a description here but the site won’t allow us.Scratch testing is a simple and rapid method of characterizing coatings, but results obtained are influenced by various factors such as coating thickness, substrate mechanical properties, .

key findings regarding the use of scratch testing method to estimate rock strength and other geomechanical properties over the past few decades. We extensively discussed the .

The scratch test is a quasi-non-destructive method made up of pushing a tool across the surface of a weaker rock at a given penetration depth. The unconfined compressive strength (UCS), fracture.Scratch Tests: A New Way of Evaluating the Fracture. Toughness of Materials. by. Ange-Therese Akono. Submitted to the Department of Civil and Environmental Engineering on . Using the scraping of butter as a starting point, the MIT engineers launched a study to see if the age-old scratch test — used by researchers to gauge a material’s properties by indenting or scratching it with a tool — could .

The scratch test is a non-destructive method made up of pushing a tool across the surface of a weaker rock at a given penetration depth. In many cases, the scratch test has now become accepted as a versatile tool for assessing the mechanical integrity of a surface, whether bulk or coated, and has found . In this study, we presented the application of the scratch test to measure uniaxial compressive strength within the ductile scratch regime and opening mode fracture toughness . The scratch test method measures the horizontal (F T ) and vertical (F V ) scratch forces, the continuous unconfined compressive strength (UCS), and the ultrasonic .

The scratch test has been used to assess the adhesion of thin hard coatings for some time now and is a useful tool for coating development or quality assurance.

testing for scratch programs

A skin prick test, also called a puncture or scratch test, checks for immediate allergic reactions to as many as 50 different substances at once. This test is usually done to identify allergies to pollen, mold, pet dander, dust mites and foods. In adults, the test is usually done on the forearm. Children may be tested on the upper back.The Scratch Test is a quasi-non-destructive method made up of pushing a tool across the surface of a weaker rock at a given penetration depth. The Uniaxial Compression Test is a destructive method of measuring the maximum axial compressive stress a rock can withstand before failing. . Dive into the research topics of 'Measurement of .

sears compression tester parts

The scratch test is a quasi-non-destructive method based on pushing a cutter across a rock sample and tracing the groove created at a given penetration depth. 5,6,[13] [14] [15][16] The scratch . The main focus of the current research study is on the modeling of the rock-cutting process using the SPH approach based on the experimental rock scratch tests conducted at the University of . A reliable and accurate estimation of liver size by physical examination is an important aspect of the clinical assessment of a patient. The scratch test uses auscultation to detect the lower liver edge by using the difference in sound transmission through the abdominal cavity over solid and hollow organs. The test is thought to be particularly useful if the .

Scratch test is a quasi-non-destructive method that measures microscale mechanical properties such as UCS, K IC , and ν of rocks (Schei et al., 2000;Richard et al., 2012;Kolawole and Ispas, 2020). Request PDF | Simulation and experimental research on residual stress of honed gear based on scratch test | The residual compressive stress on the surface of the gear after the power honing .PDF | On Jan 1, 2013, T. Richard and others published The scratch test: A high resolution log of rock strength with applications to geomechanics and petrophysics | Find, read and cite all the .

scratch testing software

The scratch test consists of a diamond stylus moving over the surface of a sample under a normal force which is increased either stepwise or continuously until a critical normal force is reached, at which point a well-defined coating failure occurs. . Related research . People also read lists articles that other readers of this article have read. Conclusion: The scratch test has very high reproducibility and overall agreement between the scratch test and USG was moderate, with a spearman ’ s rho of 0.37. The accuracy may potentially be .

The scratch test is usually performed either under a constant or a progressively increasing normal load, where the critical load is used as a measure of adhesion strength of the coatings. Instead, scratch test is generally over a long test range on material surface and can obtain abundant data, which, to some extent, can cover the drawbacks of indentation test and may provide a reliable tool to investigate the micro structure and mechanical properties of CBMs with limited costs in time and man power.

The new ASTM standard for scratch adhesion testing, ASTM C1624, covers the determination of the adhesion strength and failure modes of hard, thin ceramic coatings on metal or ceramic substrates. Scratch testers can be used for industrial quality control as well as scientific research. They should allow both lightly skilled operators and more experienced .

Therefore, the relevant research can not be directly applied to power honing. It is necessary to carry out this study on the formation and distribution of residual stress in power honing. In this study, in order to investigate the power honing process, scratch test based on gear samples as well as simulation are performed. The "Nanoindentation and Scratch Test Instruments Market" reached a valuation of USD xx.x Billion in 2023, with projections to achieve USD xx.x Billion by 2031, demonstrating a compound annual .

Although the scratch test has now become commonplace both in the research field as a measurement tool and in industry as a Quality Control (QC) tool, the utility of this technique in gaining a truly quantitative measure of the adhesion of a coating has only been approached in the past few years, with the aid of recent advances in instrumentation, analysis . Therefore, the purpose of this study is to develop a Scratch-based coding achievement test. Design/methodology/approach Initially, an item pool with 31 items was created.

The scratch test had a specificity of 61%, which was significantly lower than the specificity of thenar atrophy (96%) and significantly higher than the specificity of Durkan's test (18%) and CTS-6 .

scratch testing process

A number of tests which provide chiefly qualitative assessments of coating toughness or adhesion have been developed. For example, the scratch test has been commonly used (Chalker et al., 1991 .The scratch test thus emerges as a self-consistent technique for both cohesive–frictional strength and fracture properties that is highly reproducible, almost non-destructive, and not more sophisticated than classical compression tests, which makes this ‘old’ test highly attractive for performance-based field applications.

In this study, a large numbers of micro PDC bit drilling and scratch testing experiments were conducted in order to establish the correlation of the crushing work ratio between the two types of . Here we describe a novel assay combining the ISO 10993-5 agar diffusion test and the scratch also termed wound healing assay. . angiogenesis and anti-cancer drug research to assess bioactivity .

Indentation and scratch test methods offer alternative solutions in these cases. For the indentation method, Lawn et al. [9] proposed an indentation test method to evaluate the fracture toughness of quasi-brittle materials based on the critical fracture stress. Murty et al. [10] obtained the critical indentation depth of the quasi-brittle materials. . Byun et al. [11] proposed .

Appearance of new standards and modern devices for determining of adhesion characteristics of different coatings by scratch test creates new possibilities of those properties regulation in digital . A new approach for evaluating the wet-adhesive strength of epoxy-based coatings was carried out based on a recently standardized ASTM/ISO scratch test. A linearly increasing scratch normal load was applied during scratch to induce progressively increased delamination stress at the coating and steel substrate interface. Thus, the applied critical load to cause . The testing procedure (a scratch" test, or cutting test performed at a "small" depth of cut of typically 1 mm or less), the method of interpretation, and some experimental results are described.

sears craftsman compression tester

sears diesel compression tester

webLa Sélection Hentai 2022 d’ActuaBD. 25 décembre 2022 Nickyl. Comme nous avons pu vous présenter durant l’année écoulée une solide vingtaine des nouveautés parues dans ce genre, nous nous sommes dits qu’il ne serait pas si détonnant que cela de vous proposer notre sélection des titres qui nous ont le plus plu en 2022.

scratch test research|scratch test for coating